Products

Quality Assurance

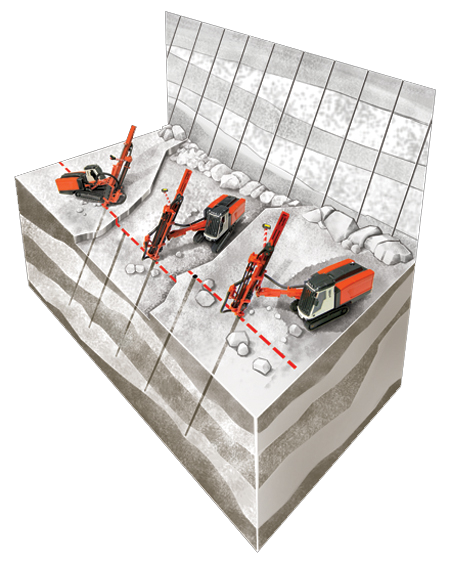

Difficult Compound Angles are pre-calculated in real-time with 0.1 degree accuracy. Entire or partial drilling pattern can be executed from on-screen created projects or from in-memory stored transferable file.

DTI AngleBlaster is a self contained setup system utilized in angular or plain blast pattern developments. Difficult Compound Angles are pre-calculated in real-time with 0.1 degree accuracy and stored. It accurately tracks the projects AZIMUTH direction in order to compensate for any changes that may effect angles and direction of the first hole for the remainder of the pattern without any operator’s interaction.

The operator simply uses touch screen instructions to precisely transfer angular setup information from the first selected hole to the remaider of the pattern without having to leave the cab or make any adjustments to specific mine oriented reference points.

The system measures and determines the next hole setup angles regardless of the positioning of the drill insuring that all blast holes are parallel and in the same plane.

FEATURES:

• Enhanced Screen Graphics.

• Capable of measuring in any plane and calculate compound angles.

• Fits all applications including boom mounted masts.

• Minimal number of components, only 4 parts.

• Proven field tested components.

• Self contained.

• No visible sight lines required. Memory capability, always references the original hole until cleared from the system. The drill can be moved from site to clear for blasts and returned without losing the original reference points.

• Works independently without requiring mine supported reference points.

• Real time reference with no lag time.

• Accurate in-hole depth measurements when utilized with the DTI Laser (optional).

• Data logging capabilities (optional).

• Easliy intergrated into the drill’s existing systems.